|

Plug-and-Play Motor Monitoring

Use Viewpoint Monitoring to Monitor Motor Protection Equipment

Monitor critical information such as:

- Number of motor starts

- Learned motor starting current

- Motor running hours

- History of motor trips

- Real time power quantities (amps, motor load)

- Motor temperature

|

|

View motor status using digital inputs, analog inputs and RTD inputs. View motor status using digital inputs, analog inputs and RTD inputs. |

| |

|

|

Supported Devices:

| M60 Motor Protection System |

239 Motor Protection System |

| 859 Motor Protection System |

MM200/MM300 Motor Management System |

| 869 Motor Protection System |

MM2/MM3 Intelligent MCC Controller |

| 469 Motor Protection System |

SPM Synchronous Motor Protection System |

| 369 Motor Protection System |

RRTD Remote RTD Module |

| 269 Motor Protection System |

|

|

|

| |

|

|

|

Plug-and-Play Transformer Monitoring

Use Viewpoint Monitoring to Monitor Transformer Protection Equipment

Monitor critical information such as:

- Transformer energization status

- Real time power quantities (amps, transformer loading, demand)

- Current harmonic analysis

- Accumulated loss of life

- Tap changer position

- Hottest transformer winding temperature

|

|

Monitor total harmonic content in each phase for all

windings.

Monitor total harmonic content in each phase for all

windings.

|

| |

|

|

|

Supported Devices:

| T60 Transformer Protection System |

845 Transformer Protection System |

| T35 Transformer Protection System |

745 Transformer Protection System |

|

|

| |

|

|

|

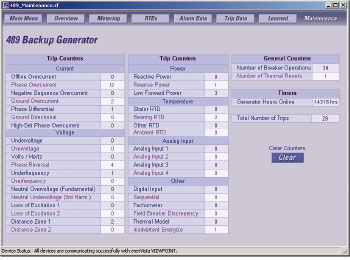

Plug-and-Play Generator Monitoring

Use Viewpoint Monitoring to Monitor Generator Protection Equipment

Monitor critical information such as:

- Generator loading

- Real time power quantities (amps, volts)

- Generator running hours

- Generator temperature

|

|

Improve maintenance efficiency by analyzing trip operations. Improve maintenance efficiency by analyzing trip operations. |

| |

|

|

|

Supported Devices:

| G60 Generator Protection System |

889 Generator Protection System |

| G30 Transformer Generator System |

489 Generator Protection System |

|

|

| |

|

|

|

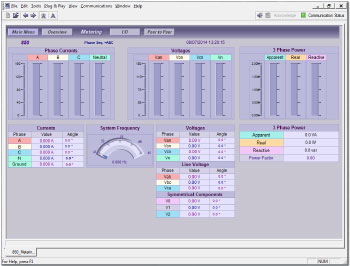

Plug-and-Play Feeder Monitoring

Use Viewpoint Monitoring to Monitor Feeder Protection Equipment

Monitor critical information such as:

- Breaker status

- Accumulated breaker arcing current

- Real time power quantities (amps, volts, demand, energy)

- Synchronism data

|

|

Easily monitor synchronism levels needed for reclosing of circuit breakers. Easily monitor synchronism levels needed for reclosing of circuit breakers. |

| |

|

|

|

Supported Devices:

| 850 Feeder Protection System |

350 Feeder Protection System |

| F60 Feeder Protection System |

F35 Multiple Feeder Protection System |

| 750/760 Feeder Protection System |

F650 Feeder Protection System |

| 735/737 Feeder Protection System |

MIFII Feeder Protection System |

|

|

| |

|

|

|

Plug-and-Play Breaker Monitoring

Use Viewpoint Monitoring to Monitor Breaker Equipment

Monitor critical information such as:

- Breaker status

- Number of breaker trip operations

- Real time current, voltage and power levels

|

|

Monitor breaker equipment with predefined screens.

Monitor breaker equipment with predefined screens.

|

| |

|

|

|

Supported Devices:

| MVT MicroVersa Trip Unit |

EMVT Enhanced Microversa Trip Unit |

| GTU EntelliGuard TU Trip Unit |

Entellisys Low-Voltage Switchgear |

|

|

| |

|

|

|

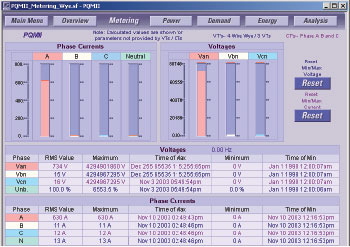

Plug-and-Play Power Quality Monitoring

Use Viewpoint Monitoring to Monitor Power Quality Equipment and Measure Usage

Monitor critical information such as:

- Power quality and equipment status

- Load unbalances using real time and maximum and minimum values

- Consumption and cost of energy using inputs from revenue meters

- Amount of total harmonic distortion on the power system

|

|

Monitor the power quality status for critical devices.

Monitor the power quality status for critical devices.

|

| |

|

|

|

Supported Devices:

| PQM / PQM II Power Quality Meter |

EPM 7000/7000P/7100 Electronic Power Meter |

| EPM 2000/2200 Electronic Power Meter |

EPM 9450/9650/9700 Electronic Power Meter |

| EPM 4600 Electronic Power Meter |

EPM 9800 Electronic Power Meter |

| EPM 5200/5300/5350 Electronic Power Meter |

EPM 9900/9900P Electronic Power Meter |

| EPM 6000/6100 Electronic Power Meter |

|

|

|

| |

|

|

|

Plug-and-Play Backup Power Monitoring

Use Viewpoint Monitoring to Monitor Critical Backup Assets

Monitor critical information such as:

- Availability of normal and emergency power sources

- Status of power source connections

- Real time voltages and frequency

- Switch status, timer settings and control switch position

- Stored events and exerciser schedules

|

|

Monitor the status of critical backup assets.

Monitor the status of critical backup assets.

|

| |

|

|

|

Supported Devices:

| MX150 Controller |

Lan Pro UPS |

| MX250 Controller |

SG-Series UPS |

| MX350 Controller |

|

|

|

Protection & Control

Protection & Control  Software

Software  EnerVista Viewpoint Monitoring

EnerVista Viewpoint Monitoring