|

GL 310 S, GL 311 S & GL 312 S

Live tank circuit breakers from 100 kV up to 145 kV

Reliable Performance in Low Temperatures

GE’s GL 310 S, GL 311 S and GL 312 S live tank circuit breakers for outdoor installation are designed for temperatures down to -30°C with pure SF6. They feature the latest technologies in interrupter chambers and spring-operated mechanisms. Our latest single-motion technology provides an optimum solution for applications within this range of minimum temperature. GE’s live tank circuit breakers provide a high level of reliability, even under extreme conditions and climates, or in highly active seismic areas. The circuit breakers are completely assembled and pre-filled at the factory before delivery, allowing for quick, easy installation and commissioning with long intervals between maintenance. Compared to other products in GE ‘s portfolio within the same voltage range, GL 310 S, GL 311 S and GL 312 S circuit breakers needs 15% less SF6 which reduces the environmental impact by 29 tons equivalent CO2. |

High performance

Right choice for temperatures down to -30°C

Reduced gas mass/ environmental impact

Safety

Easy Installation and Light Maintenance

Quality and Testing

GE's live tank circuit breakers meet the latest versions of national and international standards, such as IEC 62271-100. The entire development and production procedures are fully compliant with the latest ISO 9001, ISO 14001 and OHSAS 18001 quality standards.

High Quality Components

The GL 310 S, GL 311 S, and GL 312 S live tank circuit breakers provide high reliability based on high quality components, including :

Technical Characteristics

Product Options

Specifications

| Breaker type | GL 310 S | GL 311 S | GL 312 S |

| Rated voltage | 100 kV | 123 kV | 145 kV |

| Rated frequency | 50 Hz | 50 Hz | 50Hz |

| Rated normal current | 3,150 A | 3,150 A | 3,150 A |

| Rated short-circuit breaking current | 40 kA | 40 kA | 40 kA |

| Rated short-circuit making current | 100 kA | 100 kA | 100 kA |

| Rated duration of short-circuit | 3 s | 3 s | 3 s |

| First Pole to clear factor | 1.3/1.5 | 1.3/1.5 | 1.3/1.5 |

| Opening time | 27-37 ms | 27-37 ms | 27-37 ms |

| Breaking time | 50-60 ms | 50-60 ms | 50-60 ms |

| Closing time | ≤70 ms | ≤70 ms | ≤70 ms |

| Average ambient temperature** | -30 °C up to +40 °C | -30 °C up to +40 °C | -30 °C up to +40 °C |

| Design altitude* | 1,000 m.a.s.l. | 1,000 m.a.s.l. | 1,000 m.a.s.l. |

| Pollution level** | 25 mm/kV | 25 mm/kV | 25 mm/kV |

| * Standard values according to IEC. Higher design altitudes available on request | |||

| ** Other temperatures and pollution levels available on request | |||

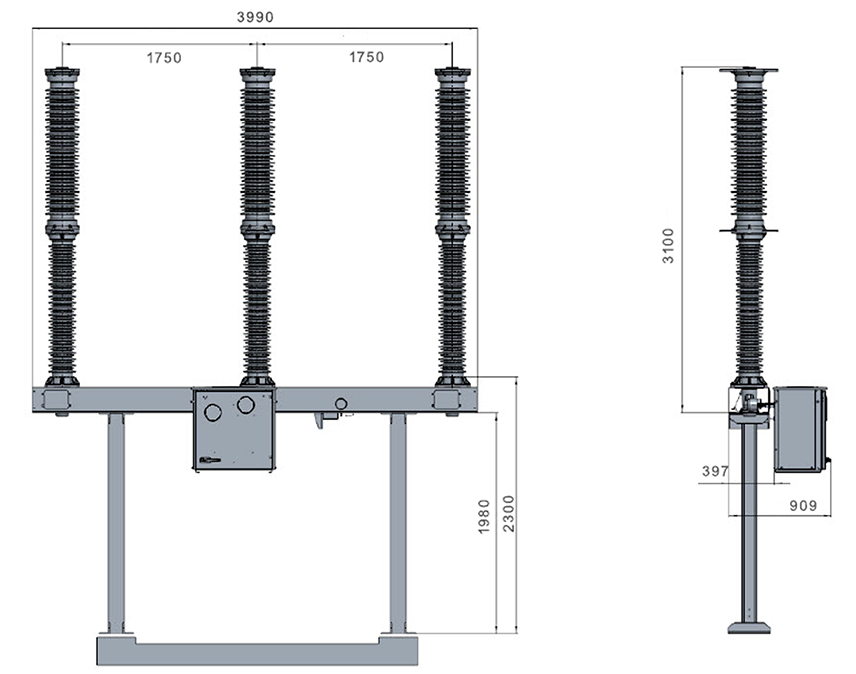

Drawings

GL 311 S/312 S – other phase center distance available on request