|

MiCOM Agile P34x

Generator Protection Systems

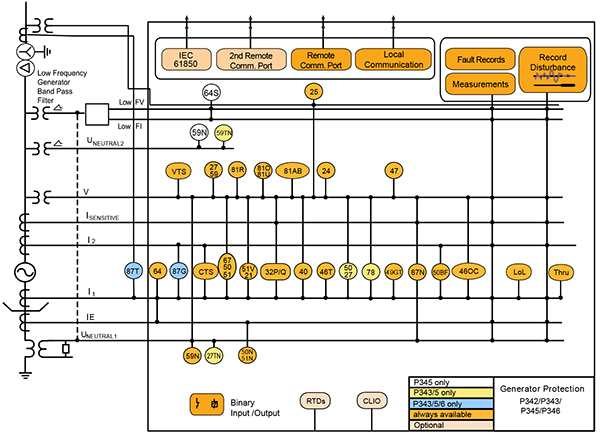

GE's MiCOM Agile P34x generator protection relays provide flexible and reliable integration of protection, control, monitoring and measurement functions for a wide range of applications. The P34x relay platform is available in six models that cover most installations from small generators to sophisticated systems including generator-transformer applications and large variable speed double fed induction pumped storage machines. Key features:

|

What's New

The new software features:

Overview

GE's Agile P34x generator protection solutions provide extensive functionality to meet all generator and generator - transformer applications, including differential protection for fast and selective tripping of phase and earth faults. All generator protection, control, monitoring, recording and communications components are housed within one box, and the solutions are accompanied by a comprehensive library of hardware options, protection and control functions to meet system requirements.

Key benefits:

Main characteristics:

ANSI ® Device Numbers and Functions

|

|

|

Agile P34x Models

|

P342 Small Generator Management IED. |

Manufacturing for P342 has been discontinued. As an alternative, please refer to 889. |

|

P343 Medium to Large Sized Generator Management IED |

|

|

P345 Large Generator Management IED with 100% Stator Earth Fault |

|

|

P346 Small Generator Management IED with Differential |

The P346 is under last-time buy. Orders may be placed until 15th June 2024 and will be fulfilled based upon availability. As an alternative, please refer to P343, 889, G60 or G30. |

|

P348 Variable Speed Double Fed Induction Machine protection IED |

Manufacturing for P348 has been discontinued. Please contact us to discuss alternatives. |

|

P391 Rotor Earth Fault Unit |

|

|

GPM-S 100% stator earth fault unit (20Hz injection), used with the P345 |

MiCOM S1 Agile

Key benefits:

Engineering Tool Suite

S1 Agile is the truly universal PC tool for MiCOM Agile relay, assemble all tools in a palette for simple entry, with intuitive navigation via fewer mouse-clicks. No-longer are separate tools required for redundant Ethernet configuration, phasor measurement unit commissioning, busbar scheme operational dashboards, programmable curve profiles or automatic disturbance record extraction – applications are embedded. MiCOM S1 Agile supports all existing MiCOM, K-Series and Modulex, including a utility for automatic conversion of setting files from previous generations of numerical relays like K-series and MiCOM P20 to the latest P40 Agile models.

To move to the future, with no loss of functionality, no loss of device support, and full compatibility with your installed base and system architecture – request a copy of S1 Agile with the contact form link below.

Key features in the MiCOM S1 family:

MiCOM S1 Agile software request

To receive the MiCOM S1 Agile, please use our Contact form. This will also ensure that you are kept up-to-date with the latest enhancements, including updates and bug fixes.

Refurbishment Solutions

GE’s latest MiCOM P340 models offer a perfect functional match for LGPG relay from the heritage installed-base brands of GEC Measurements, GEC Alsthom, Alstom and Areva:

Refurbishment Solutions – “If It’s Blue Think to Renew”

GE’s latest MiCOM P340 series models P341 to P348 inclusive offer an ideal path to refurbish an older installed base of MiCOM P340 relays. Whether those older products were initially sold as Alstom or AREVA-branded products, newer models retain pin-pin refurbishment capability. Advantageously, users can benefit from the advancements made in protection, control, communications, hardware that have taken place in the intervening years. The new P40 retains form, fit and function compatibility but delivers the latest platform and software ready for today’s environment, and for future-proofed application for the decades ahead. Pin-Pin Upgrade Methodology:

Contact us for advice and support