Key Features

Protection & Control

The 339 motor protection system is designed to protect and manage various sizes of LV and MV asynchronous motors motors and driven equipment. Flexible and powerful, the 339 provides advanced motor protection, control and monitoring in one integrated, economical drawout or non-drawout design. The 339 contains a full range of self contained protection and control elements as detailed in the Functional Block Diagram and Features table.

Block Diagram and Features table.

|

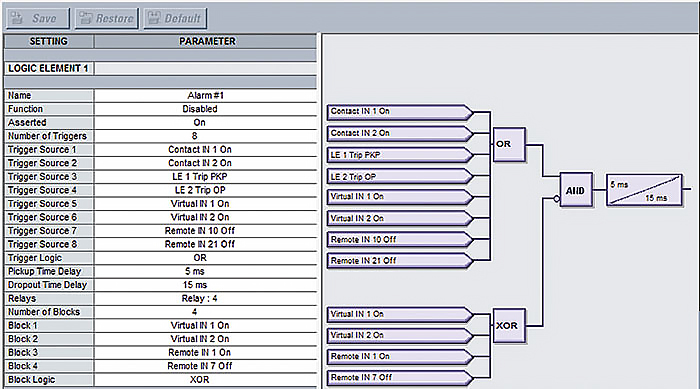

| Sixteen logic elements available for applications such as manual control, interlocking and peer to peer tripping. |

Key Features

Power System Troubleshooting

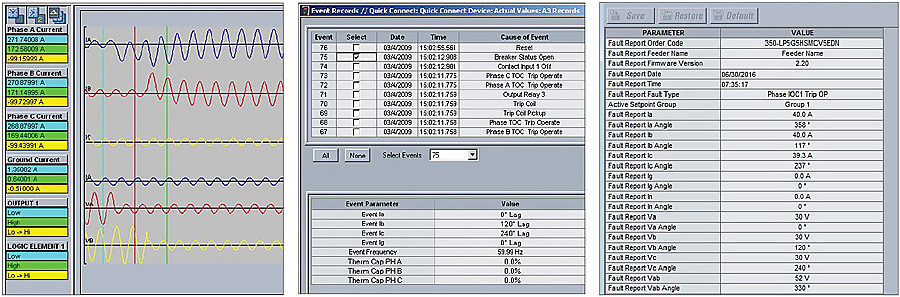

Analyze power system disturbances with transient fault recorder and event records

Metering, Monitoring & Diagnostics

The Motor Heath Report allows you to easily “see” how your motor is doing:

|

Key Features

Advanced Communications

|

The 339 utilizes the most advanced communication technologies today making it the easiest and most flexible motor protection relay to use and integrate into new and existing infrastructures. Multiple communication ports and protocols allow control and easy access to information from the 339. All communication ports are capable of communicating simultaneously. With our advanced draw-out construction, the 339 relay can be drawn-out without having to disconnect any communication cables. The 339 supports the most popular industry standard protocols enabling easy, direct integration into electrical SCADA and HMI systems. Modbus RTU is provided as standard with a RS485 networking port. The following optional protocols are available: |

|

|

|

These protocols make it easy to connect to a Utility or Industrial automation system, eliminating the need for external protocol converter devices.

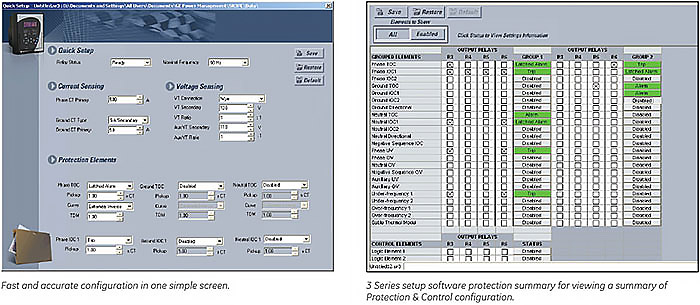

EnerVista Software

The EnerVista suite is an industry leading set of software programs that simplifies every aspect of using the 339 relay. The EnerVista suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate the information measured into DCS or SCADA monitoring systems. Convenient COMTRADE and sequence of event viewers are an integral part of the 339 set up software and are included to ensure proper protection and system. Learn More

Feeder protection settings in one easy step

Access Control

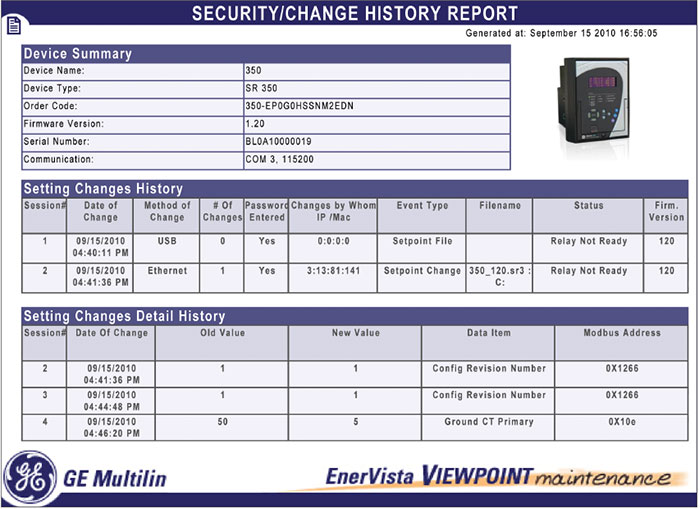

Multilin devices and relays are designed with simple but powerful security to enable reliability and compliance for virtually any project or implementation. Password security is an optional feature of the 3 Series which can be setup using the SR3 EnerVista Setup software. The password system has been designed to facilitate a hierarchy for centralized management. This is accomplished through a Master level access password which can be used for resetting lower level access passwords and higher level privileged operations.

Auditing and Reporting

With the Security Audit Trail reporting feature, available in GE’s ViewPoint Monitoring software, operators are able to obtain Event logging reports of key activities such as configuration changes. These pre-formatted reports can be used to help ensure device and protection system integrity and perform forensic auditing of activities and changes for compliance.

Trace any setting changes with security audit trail.

Hardware

Inputs and Outputs

The 339 features the following inputs and outputs for monitoring and control of typical motor applications:

Drawout & Non-Drawout Construction

The 339 is offered in both a drawout or a non-drawout construction. In the drawout case design the 339 simplifies installation and improves site safety as the need to open switchgear doors or rewire the device after testing is eliminated.

The 339 protection relay chassis used with a draw out relay is available separately, for use as a partial replacement or in test environments. The draw out relay with no chassis is also available to order as a spare unit.

Application Flexibility & Ease of Wiring

Removable terminals ease wiring and in-system testing or troubleshooting.

Optional RTD

Reduce wiring via remote RTD’s using the RMIO module and support for 3 internal RTDs

Drawout

Drawout

Non-drawout

Non-drawout

Remote RTD Module

Remote RTD Module

|

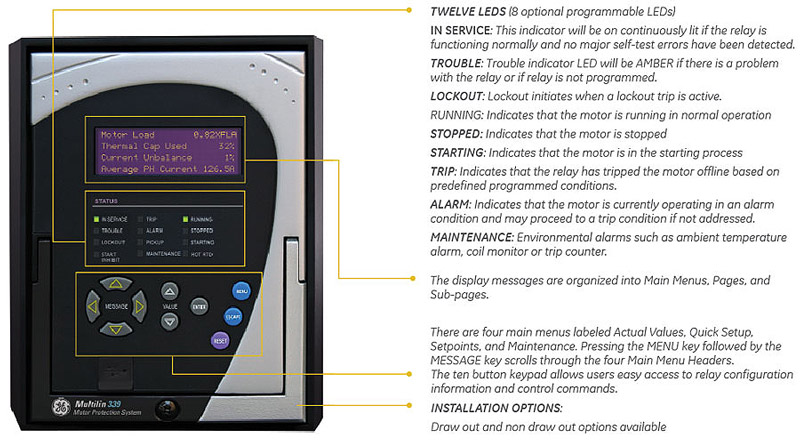

User Interface

Retrofit Existing Multilin MII Family Devices

Traditionally, retrofitting or upgrading an existing relay has been a challenging and time consuming task often requiring re-engineering, panel modifications and re-wiring. Similar features and form factor of some models of MII family devices allow users to replace their existing relays with 3 Series relays with enhanced protection and control features and advanced communications.

The SR3 EnerVista Setup software allows users to create new setting files based on existing MIFII and MIVII setting files and can be uploaded to a 350 relay with a compatible model number. Retrofit is smooth and simplified with minor wiring or switchgear modifications.